Calculating Labour Cost

We start by calculating how much a minute of a worker should cost to cover the costs of running the factory.

This is done by calculating the annual factory cost which consists of these parts:

This Annual Factory Cost is divided by the time the workers can produce garments in a year. This gives us how much a minute of a workers time needs to be attributed to cover the factory costs. Let's calculate how many minutes the factory can yield:

Workers (100) * Workdays (300) * Minutes (480) = 14.400.000 Minutes

So if the factory has 1000 workers then they will have ~150m sewing minutes a year. As a rule of thumb, you can simply multiply 150.000 with your vendor's factory worker number and you will get the annual minute capacity. That's because one worker works roughly 150.000 minutes a year.

So how much should a sewing minute cost?

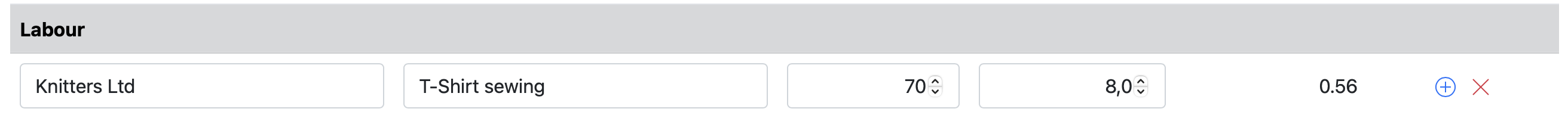

Let's assume that the annual factory costs of the 100 worker factory is €1m. Then each worker sewing minute is €1m / 14,4m minutes = €0.07 = ¢7. Each minute a worker is sewing your products you should add ¢7. We have a table of how long it takes to produce certain product types, multiply the two and that's your labour item in your BOM. A T-shirt takes ~8 worker minutes to product so that's €0,56:

Standard Allowed Minutes (SAM)

It's important to bear in mind that the SAMs are averages and the more complex the product is the longer it will take (and how much the actual number could deviate from the average).

| Product Type | SAM (minutes) | Range (+/-) |

|---|---|---|

| T-Shirt | 8 | 6 to 12 |

| Polo Shirt | 15 | 10 to 20 |

| Blouse | 18 | 15 to 45 |

| Bra | 18 | 16 to 30 |

| Formal Shirt | 21 | 17 to 25 |

| Formal Trouser | 35 | 20 to 50 |

| Hoodie | 45 | 35 to 55 |

| Suit Jacket | 100 | 70 to 135 |

So ask your garment manufacturer for the Sewing Minute rate and SAM (Standard Allowed Minutes). The endgoal is to ensure that 1) your supplier's workforce get a decent wage and 2) you can very likely get workers to get paid well without increasing the FOB price. Probably you can still reduce the FOB price and increase worker's pay, as long as you have all the facts on the table for a proper negotiation.

Source: Own research, Online Clothing Study